Private label manufacturing is a process where a manufacturer creates products that are sold under another company’s brand. This approach allows businesses to offer products with their own branding, packaging, and marketing, without needing to produce the goods themselves. Unlike other manufacturing methods, private label manufacturing gives the business complete control over the product’s presentation and how it aligns with their brand’s identity.

This method is different from white labeling, where the same product is sold by multiple brands with minimal differences. With private label manufacturing, businesses can customize products to better meet the needs and preferences of their target audience.

The Benefits of Private Label Manufacturing

By owning their brand, companies gain full control over branding, packaging, and marketing, enabling them to create a distinct market identity. Additionally, leveraging economies of scale often associated with large-scale production leads to cost reductions, allowing for competitive pricing and improved profit margins.

Private label manufacturing also provides flexibility. Businesses can swiftly adapt product designs, packaging, or formulations to align with evolving customer preferences and market dynamics. This agility is crucial for staying competitive.

Key Considerations Before Starting Private Label Manufacturing

Before starting with private label manufacturing, there are several important factors to consider. Market research is essential. Understanding the target market, customer needs, and the demand for the product is crucial for success. Without proper research, businesses risk launching products that may not resonate with their audience.

Choosing the right manufacturer is another critical step. A reliable manufacturing partner is key to producing high-quality products. Businesses should evaluate potential manufacturers based on factors such as their production capacity, quality control measures, and ethical practices. It’s important to work with a manufacturer who can consistently deliver products that meet the brand’s standards.

Product development is also a significant consideration. The process involves creating a product design, developing a prototype, and ensuring that the product complies with industry regulations. Branding strategy is another essential aspect.

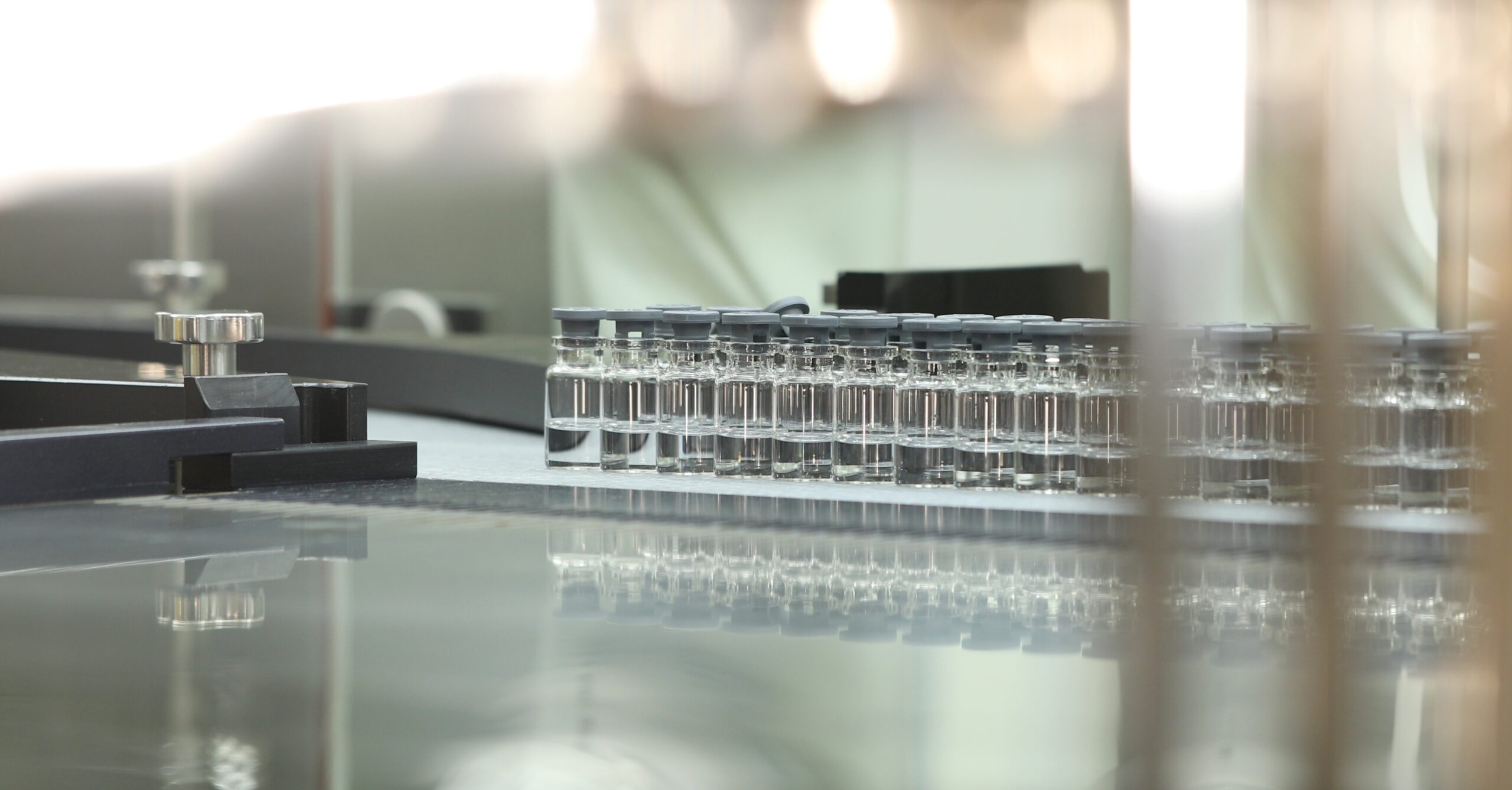

The Process of Private Label Manufacturing

The process of private label manufacturing involves several steps. It typically begins with product ideation and design. At this stage, businesses work on creating product concepts that align with their brand’s vision. This is followed by prototyping, where a sample product is developed to test its functionality and appeal.

Once the prototype is approved, the next step is production. The manufacturer scales up production to meet the required quantity, ensuring that each batch maintains consistent quality. During production, businesses must manage lead times and inventory to avoid delays and shortages.

Quality control is an ongoing process throughout production. Packaging and labeling are also important. The product’s packaging should reflect the brand’s identity and appeal to the target audience. Finally, distribution and logistics are planned to ensure the product reaches the market efficiently. This includes warehousing, shipping, and managing the supply chain.

Common Challenges in Private Label Manufacturing and How to Overcome Them

Private label manufacturing comes with its own set of challenges. Quality control issues can arise, especially when scaling up production. Consistent quality is essential to maintaining customer trust and brand reputation. To address this, businesses should establish strict quality control protocols and work closely with the manufacturer to ensure that these standards are met.

Supply chain disruptions are another common challenge. Delays or shortages in raw materials can impact production schedules and lead to missed deadlines.

Intellectual property concerns are also important. Protecting the brand and product design from potential infringements is crucial. Businesses should take legal steps to safeguard their intellectual property and regularly monitor the market for any violations. Regulatory compliance is another challenge, especially in industries with strict standards. Staying up to date with regulations and working with manufacturers who prioritize compliance can help avoid legal issues.

The Future of Private Label Manufacturing

The private label manufacturing industry is undergoing significant transformation. A notable trend is the rising consumer demand for sustainable products. Businesses are adapting by incorporating eco-friendly practices into their manufacturing processes. This presents a prime opportunity for companies to differentiate their brands by offering products that resonate with environmentally conscious consumers.

Technological advancements are also shaping the future of private label manufacturing. Automation, artificial intelligence, and digital tools are making the manufacturing process more efficient and reducing costs. These technologies are helping businesses streamline production, improve quality control, and respond more quickly to market changes.

Consumer preferences are also influencing the future of private label manufacturing. The trend is likely to continue, with businesses finding new ways to tailor their products to individual customer needs.

Understanding Private Label Manufacturing

Private label manufacturing offers businesses a unique opportunity to create products that reflect their brand’s identity and meet customer needs. Thorough understanding of the benefits, challenges, and considerations associated with private label manufacturing empowers businesses to make informed decisions and achieve successful implementation. Whether you’re looking to differentiate your brand, increase profit margins, or offer more customized products, private label manufacturing can be a valuable strategy.

Contact Us Today

If you’re ready to explore private label manufacturing for your business, contact Yellow Emperor today to learn how we can help you create high-quality products that align with your brand’s vision.