Contract manufacturing allows companies to delegate the production of their products to a different company. Instead of handling manufacturing in-house, businesses hire external firms to make their goods. This approach allows companies to focus on their core activities, like design and marketing, while leaving production to experts.

Contract manufacturing has several benefits. It helps businesses save on costs because they don’t need to invest in manufacturing facilities or equipment. Additionally, it allows companies to tap into the specialized knowledge and technology of manufacturing firms.

Understanding Contract Manufacturing

Contract manufacturing involves a partnership where one company handles the production of products for another. There are different types of contract manufacturing arrangements.

Original Equipment Manufacturers (OEMs) produce products based on another company’s designs. Original Design Manufacturers (ODMs) take it a step further by creating both the design and the product. Private label manufacturers produce goods that are sold under another company’s brand name.

Each type of arrangement has its advantages. OEMs are ideal for companies that have specific designs but lack the resources for manufacturing. ODMs are useful for businesses that want a full-service approach, from design to production. Private label manufacturing is perfect for companies that want to offer products under their own brand without handling the production.

What is Liquid Contract Manufacturing?

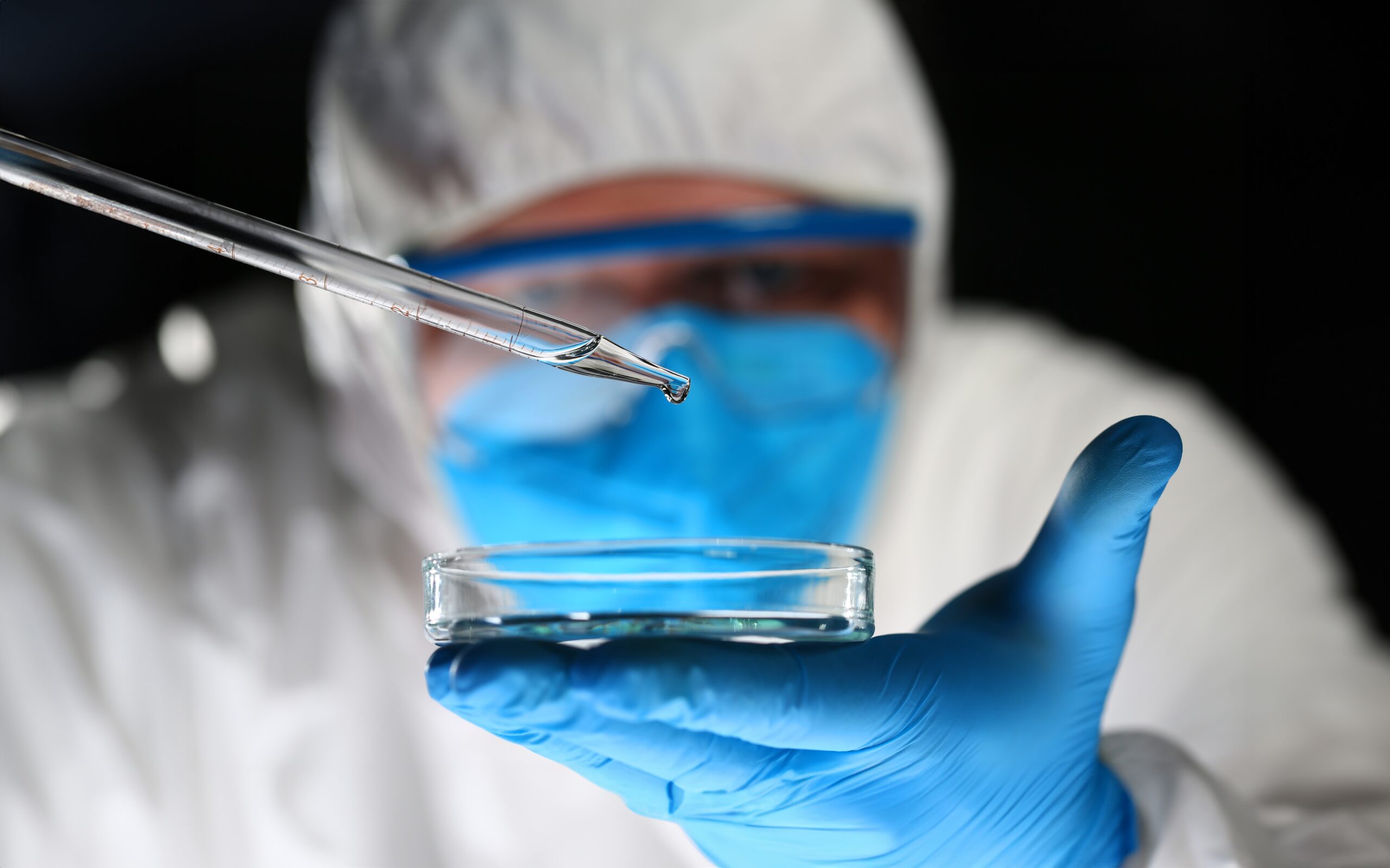

Liquid contract manufacturing is a specialized form of contract manufacturing focused on liquid products. This includes items like dietary supplements, medicines, and beauty products. Unlike solid products, liquid products require specific equipment and processes to ensure quality and consistency.

Liquid contract manufacturing involves working with manufacturers who have the expertise and equipment needed to produce liquid formulations. These manufacturers handle the entire process, from mixing and filling to packaging and labeling. They ensure that the products meet all necessary standards and regulations.

Industries That Use Liquid Contract Manufacturing

Several industries rely on liquid contract manufacturing to produce their products.

In the supplement industry, liquid contract manufacturing is used to create a variety of health and wellness products. These include vitamins, minerals, and herbal extracts. Manufacturers ensure that these products are made with high-quality ingredients and meet health and safety standards.

The pharmaceutical industry also uses liquid contract manufacturing for medicines and treatments. This includes prescription and over-the-counter drugs that come in liquid forms, such as syrups and solutions. Ensuring the correct dosage and effectiveness is crucial in this field, so manufacturers follow strict guidelines.

Cosmetic companies turn to liquid contract manufacturing for products like lotions, serums, and shampoos. These products often involve complex formulations that require precise mixing and processing. By outsourcing production, cosmetic brands can focus on product development and marketing.

Benefits of Liquid Contract Manufacturing

Liquid contract manufacturing offers several advantages.

Expertise and Technology

One major benefit is access to specialized equipment and technology. Liquid products often require advanced machinery to ensure proper mixing and consistency. Manufacturers invest in these technologies, allowing businesses to benefit without having to make significant capital investments.

Another advantage is the expertise of the manufacturing teams. They have experience with complex liquid formulations and can ensure that products meet all quality and regulatory requirements.

Cost-Effectiveness

Outsourcing production can be more cost-effective. Businesses bypass the costs of establishing and maintaining their own manufacturing facilities, paying only for the production services they require, which can be more economical.

Economies of scale are another benefit. Manufacturers can produce large quantities of products, which often leads to lower costs per unit. This can be advantageous for companies looking to keep production costs down.

Quality and Compliance

Quality is essential in liquid contract manufacturing. Manufacturers adhere to rigorous quality control procedures to ensure that products are safe and effective. They also follow industry regulations, helping companies avoid legal issues and maintain the integrity of their products.

Experience and Reputation

Experience in the specific industry and with similar products is important. A strong reputation can indicate reliability and high-quality standards.

Regulatory Certifications

Check for necessary certifications like GMP (Good Manufacturing Practice). These certifications show that the manufacturer follows industry standards and maintains high quality.

Questions to Ask Potential Manufacturers

When evaluating manufacturers, ask about their production capabilities. Make sure they can handle your product’s volume and complexity. Ask about their quality assurance processes to make sure they meet your standards. Also, discuss lead times and flexibility to see if they can adjust to your needs.

Conclusion: Making the Most of Liquid Contract Manufacturing

Liquid contract manufacturing can be a valuable solution for businesses looking to produce liquid products efficiently and cost-effectively. By partnering with experienced manufacturers, companies can tap into specialized expertise, advanced technology, and economies of scale.

If you are exploring liquid contract manufacturing options, contact Yellow Emperor today to learn how we can help meet your production needs.